Product Description Nanjing Clover Medical Technology Co., Ltd.. Items/Model TS50(PLC) Picture Burn Rate 50 kg/hour Feed Capacity 100kg Control Mode PLC Combustion Chamber 560L Internal Dimensions 100x80x70cm Secondary Chamber 280L Smoke Filter Chamber Yes Feed Mode Manual Voltage 220V Power 0.7Kw Oil Consumption (kg/hour) 12.1–24 Gas Consumption (m3/hour) 9.9–26.1 Temperature Monitor Yes Temperature Protection […]

Item Specification Model YD-30C Main Product List Primary Combustion Chamber(Main body stainless steel) Secondary Combustion Chamber(Main body stainless steel) Mix-Combustion Chamber Wet Scrubber( Washing Tower)(Main body stainless steel) Incinerator Control Case Chimney:5.0Meters *(upgrade to Stainless Steel, free cost) Italy gas burner: 02 sets Oil Tank (if oil fuel): 100Liters Automatic PLC controller incinerator plant with […]

Primary Combustion Chamber Secondary Combustion Chamber Smoke Filter Chamber Incinerator PLC Control Case Chimney:6.0Meters *(upgrade to Stainless Steel, free cost) Italy oil burner: 04 sets Oil Tank (if oil fuel): 800Liters The secondary chamber must comply with the following minimum criteria: “• Heavy steel construction small scale incinerators incinerator burner • An excess air and high temperature operational mode. • Sufficient size and appropriate geometry to achieve a gas temperature of at least 1000 Celsius for a retention time of at least 2 seconds when pre-heated and correctly operated. • Sufficient forced air inflow and airflow and fuel supply controls to ensure an exhaust gas oxygen content range of 6-12% at all times. • Hot face refractory concrete-ceramic suitable for thermal shock up to 1400 Celsius and abrasion. Minimum thickness 150mm. • Cold face refractory lining of calcium silicate or superior material, minimum thickness 100mm. • Refractory lining of all the ducts shall be done with refractory castings. Superior quality ceramic wool shall be used at all hot duct flanges and expansion joints • An electrically powered fan forced air supply, with the capacity for variation by the operator. • One or more fuel burners designed to use diesel fuel type 2 (vehicle standard) equipped with a spark igniter. • A digital thermometer with connected to an electronic datalogger. The thermometer shall be located on the chamber wall away from the fuel burner. Medical Waste Incineration Treatment Average 1000-1500 kg/hour Average 6000kg/feeding PLC(Programmable Logic Controller Incinerator) 4800Liter A heat exchanger to pre-heat air destined for the primary chamber is not compulsory but recommended. The combustion air systems and fans shall be designed to ensure high combustion efficiency and avoid a reducing (corrosive) atmosphere, incomplete burnout of the flue gases and related problems. It should also be possible to heat the primary air from 10°C to approximately 145°C, depending on the waste composition and moisture content. “The incinerator shall be designed and equipped to be installed, commissioned and operated in such a way as to prevent emissions into the air giving rise to significant ground-level air pollution; in particular, exhaust gases shall be discharged in a controlled fashion by means of a stack the height of which is calculated in such a way as to safeguard human health and the environment. All incinerators shall meet the following emission and operating standards: • Combustion efficiency (C.E.) shall be at least 99.0% • The combustion efficiency shall be computed as follows: • The diameter of the stack shall be selected by the Contractor to deliver an exhaust exit velocity of not less than 10 metres per second vertically upwards when at full scale operation. • An emission stack sampling port shall be included immediately above the secondary chamber. ” Controlled hygienic, mechanical or automatic feeding methods must not negatively influence the air supply and temperature in the primary and secondary chambers of the incinerator. “Each unit shall include a diesel fuel storage tank of sufficient capacity to enable operation of the unit for 5 working days of 10 hours each. • The unit shall include a pumping system and lines to supply the burners from the tank and the diesel-electric generator. The pumping system will have two pumps in parallel for redundancy. • The supply lines will be fabricated from steel tubing and adequately protected and supported against damage during operations and include shutoff valves for each line. • The unit shall be equipped with a fuel meter. “Incinerators must be able to support different power sources (PV solar system , diesel Electric generator , local or compound mini-scale grid) The proposed incinerators shall be able to be completely packed into a series of 20ft export standard sea containers. All electrical connections attached with the incinerator and other machinery should be provided with suitable and necessary safety devices and be protected by steel conduits, cable trays, and supports. The manufacturer should permanently mark on the incinerator indicating: (i) manufacturer’s name or trademark (ii) style, type, model or, date of manufacture of the incinerator (iii) capacity in terms of net designed heat release in heat units per timed period (i.e., British Thermal Units per hour, mega joules per hour, kilocalories per hour). “The unit shall be supplied with a lockable operations store, that shall be initially supplied with the following consumables: • A first aid kit, suitable for addressing the hazards presented by the unit. • 5 full sets of personal protective clothing and equipment. • Operating logbooks. […]

Basic Info. Pullution Sources:Solid Waste Processing Processing Methods:Combustion Export Markets:Global Additional Info. Trademark:clover Product Description Item Specification Model YD-30 YD-50 YD-100 YD-150 YD-300 YD-500 Burning Rate 30kgs/Hour 50kgs/Hour 100kgs/Hour 150kgs/Hour 300kgs/Hour 500kgs/Hour Main Product List Double Combustion Chamber Mix-Combustion Chamber Smoke Filter Chamber Control Case Stack Italy oil/gas burner: 02 units Oil Tank (if […]

Incinerator, incineration equipment to burn material you want to burn. most of time, Incinerator for waste burning, including solid waste, liquid waste and gas waste. the Incinerator fuel including oil, gas, coal, wood, etc. the fuel function for start burn, keep waste burn or only keep burn itself to get high temperature. Incinerator request 1/2/3/more […]

WWW.HICLOVER.COM|Waste Incinerators |Auto Roll Air Filters Nanjing Clover Medical Technology Co.,Ltd. Tel: +86-25-8461 0201 Mobile: +86-13813931455(whatsapp/wechat)Website: www.hiclover.com Email: sales@hiclover.comEmail: hicloversales@gmail.com Items/Model TS75(PLC) Principle Medical Waste Incineration Burn Rate Average 75 kg/hour Feed Capacity Average 120kg Control Mode PLC(Programmable Logic Controller Incinerator) Combustion Chamber 640L Internal Dimensions 100x80x80cm Secondary Chamber 280L Smoke Filter Chamber Yes Feed Mode Manual Voltage 220V Power 0.7Kw Oil Consumption (kg/hour) Average […]

Clover Incinerator update A model incinerator for pet cremation and animal incineration. New design accept independent movable platform in-out incinerator combustion chamber. This new design is valid for model A900 and bigger model. Items/Model A900 A1200 A1500 A2400 A4000 A5500 Burning Rate *animal 30 kgs/Hr. 60 kgs/Hr. 90 kgs/Hr. 150 kgs/Hr. 200 kgs/Hr. 400 kgs/Hr. […]

Product Description Items/Model YD-30 YD-50 YD-100 YD-150 Burning Rate (kgs/Hour) 30 kgs/Hr. 50 kgs/Hr. 100 kgs/Hr. 150 kgs/Hr. Feed Capacity (kgs) 60 kgs 150 kgs 200 kgs 300 kgs Equipment Weight 2300 kgs 4000 kgs 4300 kgs 7000 kgs Primary Chamber (Liters) 360 900 1200 1500 Secondary Chamber (Liters) 200 200 500 500 External Dimensions […]

She confirmed the company managed to use money from its reserves to help with the purchase. However, CPASA is still looking for donations to help make up the cost and to help with the maintenance of equipment. The incinerator is located in the Princeton Police Department. A weapon and a shelter still has to be […]

we create small scale waste incinerators, the potential from 10kgs,20kgs,30kgs,50kgs,100kgs per hour. Key Features: * High speed, from 10kgs to 600kgs per hour, up to 10ton per day. * High fever, long life of incinerator. * Free or minimal installation onsite. * One year guarantee on incinerator and parts in stock.

This model is small-scale animal cremation equipment for small pets and animals. Construction is dual/double combustion chamber with 02 units oil/gas burner, batch load incineration equipment. Animal feed chamber is 360Liters (Model: A360). Primary & Secondary combustion chambers and included mix-combustion chamber, smoke filter chamber with firebrick and Refractory Concrete chamber(as quotation detail). Batch load […]

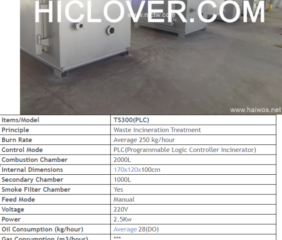

MOGADISHU SOMALIA WASTE INCINERATOR TREATMENT – TS300( PLC) Incinerator Items/Model HICLOVER TS300(PLC) Burn Rate (Average) 300 kg/hour Feed Capacity(Average) 400kg/feeding Control Mode PLC Automatic Primary Combustion Chamber 2000Liters(2.0m3) Internal Dimensions 1700x1200x1000mm Secondary Chamber 1000Liters(1.0m3) Smoke Filter Chamber Yes Feed Mode Manual Voltage 220V Power 2.5Kw Burner Type Italy Brand Oil Consumption (kg/hour) 28 N.Gas Consumption […]

Basic Info. Pullution Sources:Solid Waste Processing Processing Methods:Combustion Export Markets:Global Additional Info. Trademark:nanjing clover Origin:Nanjing Product Description Incinerator is a incineration equipment, direct fire squander by gas fuel or oi fuel. As different circumscription, incinerator could be termed many words as under: Therapy ability: Small scale incinerator, large scale incinerator and incineration pant. Waste substance: […]